Food safety managers like to keep their production lines fully stocked so that all ingredients for every dish are readily available and in abundant supply, but there are foodborne illness hazards that can occur if you stock your lines improperly. Whether you call it rotating product, flipping your lines or simply stocking a quick access station, you should make sure that you’re doing it properly to reduce the risk of spreading illness.

How Food Safety Managers Reducing Foodborne Illness while Stocking Production Lines

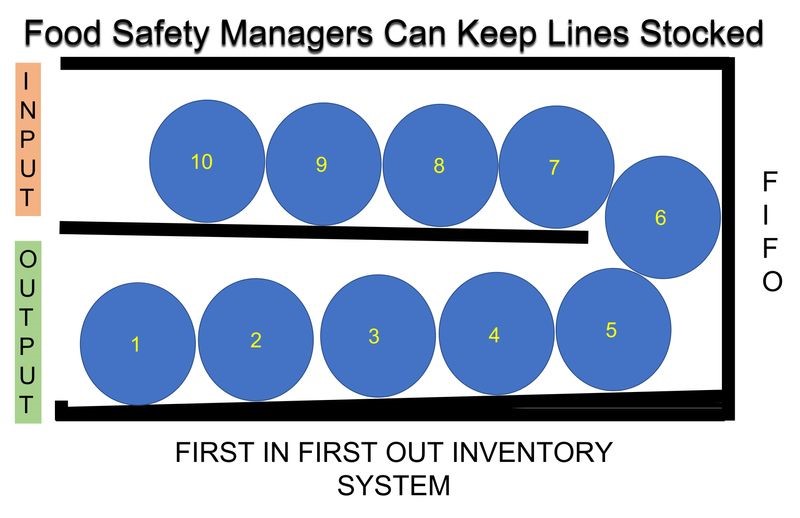

The most important thing to consider when stocking your production lines is that the oldest ingredients should be used first. Whatever method you use to stock your lines must take this into consideration. If you simply refill or top off storage containers, the oldest product will remain on the bottom and eventually begin to go bad contaminating all other product in the same container. When keeping your lines stocked, a first-in-first-out (FIFO) philosophy must be employed.

During food safety manager training classes, we’ve had a few discussions on stocking production lines, and it’s been asked if topping off containers and rotating product into clean containers is an acceptable method. While it sounds like a good idea to have a clean storage container every shift, you’re still running the risk of old product contaminating fresh ingredients. Imagine a pan filled with cheese that is one-third empty when you rotate it, and then you use one-third before the next time you rotate it, how fresh is the middle third? If you simply top off product and rotate it into a clean container, you may need an archeologist to date the product that has been trapped in the middle of your storage container every time you flip your lines.

Our suggestion is to have backup containers readily available rather than fill old containers with new product or rotate mixed-date products into new storage vessels. This will guarantee that fresh product doesn’t mix with older product that could be in danger of spoilage.

Do you have an effective strategy for keeping your ingredients stocked without mixing old and new product?